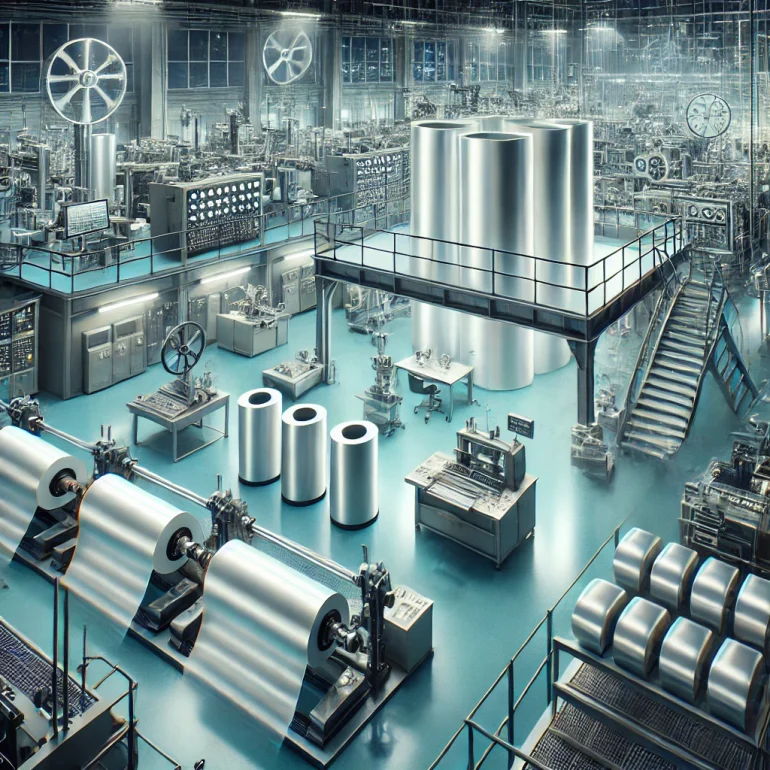

Water soluble films are revolutionizing the packaging industry with their environmentally friendly properties and versatile applications. These films dissolve completely in water, leaving no residue, making them an ideal choice for various uses in packaging, agriculture, healthcare, and more. This article explores the benefits, applications, and considerations when choosing water soluble films.

What is Water Soluble Film?

Water soluble films are made primarily from polyvinyl alcohol (PVA), a synthetic polymer that dissolves in water. These films are designed to break down quickly and completely when exposed to water, making them an eco-friendly alternative to traditional plastic films. They are available in various thicknesses and can be customized to meet specific needs.

Benefits of Water Soluble Film

- Environmental Sustainability

- Biodegradable: Water soluble films decompose into non-toxic components, reducing environmental impact and contributing to sustainability efforts.

- Reduced Plastic Waste: By replacing conventional plastic films, water soluble films help minimize plastic waste in landfills and oceans.

- Convenience and Safety

- Ease of Use: These films offer convenience in applications like single-dose packaging, where they dissolve easily without the need for additional handling.

- Safe Handling: Water soluble films provide a safe way to handle hazardous substances, reducing the risk of exposure and contamination.

- Versatility

- Multiple Applications: Water soluble films are used in various industries, including agriculture, healthcare, detergents, and packaging.

- Customizable Properties: The films can be tailored for specific dissolution rates, thicknesses, and mechanical properties to suit different applications.

- Cost Efficiency

- Reduced Packaging Costs: The use of water soluble films can lead to cost savings in packaging by eliminating the need for secondary containers and reducing waste disposal costs.

Applications of Water Soluble Film

- Packaging

- Single-Dose Packaging: Commonly used for detergents, cleaning agents, and personal care products, water soluble films provide convenient single-dose packaging that dissolves in water.

- Food Packaging: Edible films can be used for food packaging, ensuring that there is no waste left behind.

- Agriculture

- Pesticide Delivery: Water soluble films are used to deliver pesticides and fertilizers, reducing environmental contamination and ensuring precise application.

- Seed Coating: These films can be used to coat seeds, providing protection and aiding in controlled release of nutrients.

- Healthcare

- Medical Supplies: Water soluble films are used for packaging medical supplies and pharmaceuticals, ensuring safe and hygienic delivery.

- Laundry Bags: Hospitals and healthcare facilities use water soluble laundry bags to safely handle contaminated linens, which dissolve during the washing process.

- Industrial Applications

- Chemical Packaging: These films are ideal for packaging chemicals, as they prevent direct contact and ensure safe handling and disposal.

- Textile Industry: Water soluble films are used in the textile industry for applications like embroidery, where they dissolve after use.

Key Considerations When Choosing Water Soluble Film

- Dissolution Rate

- Application Requirements: Choose a film with a dissolution rate that matches the requirements of your specific application. Some applications may require quick dissolution, while others may need a controlled release.

- Thickness and Strength

- Durability: Consider the thickness and mechanical strength of the film to ensure it can withstand the demands of its intended use without breaking prematurely.

- Compatibility

- Chemical Compatibility: Ensure the film is compatible with the substances it will come into contact with, especially if used for packaging chemicals or pharmaceuticals.

- Environmental Conditions

- Temperature and Humidity: Assess the environmental conditions where the film will be used and stored, as these factors can affect its performance and dissolution.

- Regulatory Compliance

- Standards and Certifications: Verify that the water soluble film meets relevant regulatory standards and certifications for your industry, ensuring safety and compliance.

Leading Suppliers of Water Soluble Film

- MonoSol

- Overview: MonoSol is a global leader in water soluble film technology, known for its innovative and high-quality products.

- Applications: Their films are widely used in detergents, agrochemicals, and medical applications.

- Kuraray

- Overview: Kuraray specializes in PVA films and offers a range of water soluble films for various industries.

- Quality and Innovation: Kuraray is recognized for its commitment to quality and continuous innovation.

- Aicello

- Overview: Aicello provides water soluble film solutions with a strong focus on customer satisfaction and environmental sustainability.

- Industry Presence: Their films are used in automotive, electronics, and consumer goods sectors.

- Sekisui Specialty Chemicals

- Overview: Sekisui offers high-performance water soluble films known for their durability and reliability.

- Sustainability: Sekisui emphasizes sustainable practices and eco-friendly products.

- AMC (UK) Ltd

- Overview: AMC (UK) Ltd is a key player in the European market, providing customized water soluble film solutions.

- Customization: They offer tailored solutions to meet specific customer needs and applications.

Conclusion

Water soluble film offer a sustainable, versatile, and cost-effective solution for various applications across multiple industries. By choosing the right film based on dissolution rate, thickness, compatibility, and environmental conditions, businesses can enhance their packaging, agricultural, healthcare, and industrial processes. Leading suppliers like MonoSol, Kuraray, Aicello, Sekisui, and AMC (UK) Ltd provide high-quality water soluble films that meet diverse needs and promote environmental sustainability.